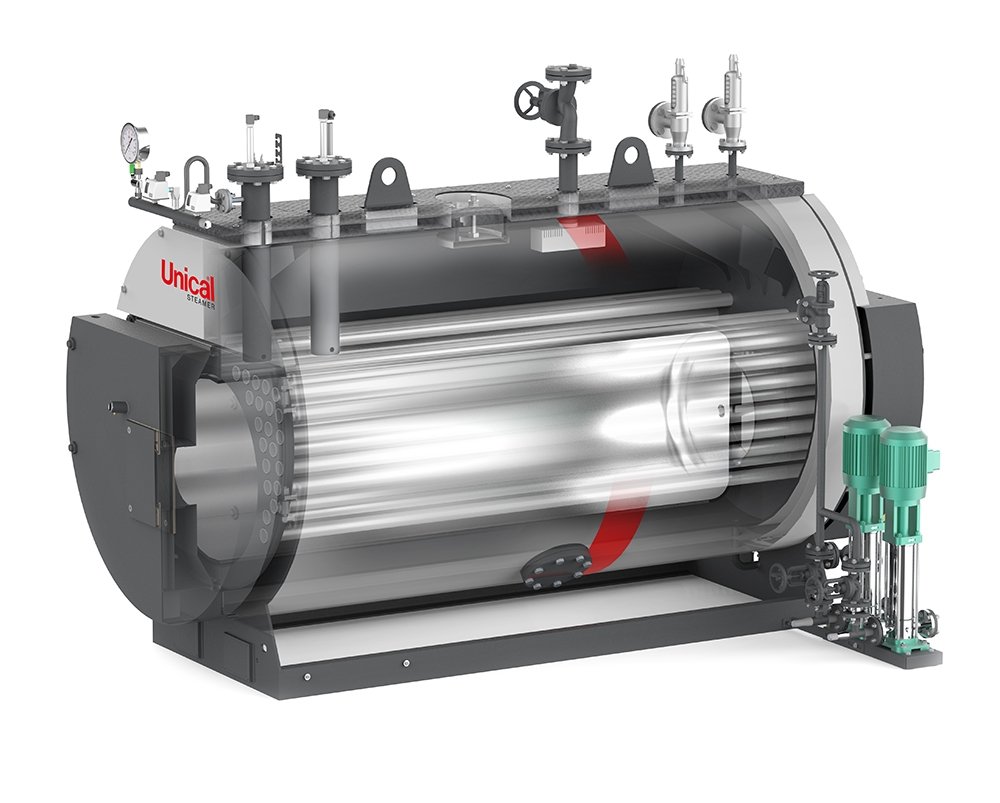

ANH High-Pressure Steam Generator:

The ANH High-Pressure Steam Generator is a robust system featuring flame inversion, smooth tubes, and turbulators, designed for optimal efficiency. With efficiency ratings of 90% for the OR version, 94% for the HP version, and up to 96% for EC versions, the BAHR’12 series offers exceptional performance in steam generation.

Key Features:

– Flame inversion principle with a wet bottom design

– Standard safety pressure up to 12 bar (higher pressures available on request)

– Steam production ranging from 300 to 6000 kg/h

– Compatible with liquid or gaseous fuels

– Complete with adjustments and safety accessories for automatic operation

– Conforms to Essential Safety Requirements of European Directive PED 2014/68/EU, evidenced by CE marking

General Characteristics:

– Boiler body designed in compliance with EN 12953-3:2016 standard, featuring set-in type tube plates and a cylindrical shell with a high-quality steel wet bottom furnace

– Equipped with safety and control devices housed in 100 mm diameter still pipes

– Materials accompanied by manufacturing certificates, ensuring suitability for use

– Smoke pipes welded to tube plates, with each tube featuring helical or inserted turbulators

– Front door constructed from welded steel sheet internally lined for insulation, with a self-cleaning flame sight glass

– Rear smoke chamber made of welded steel sheet, designed for easy removal, and equipped with suitable cleaning door and flue gas connection

– Base comprises a steel frame closed by steel plates

– Service gangway located in the upper part of the generator, compliant with EN ISO 14122 Standard

– Thermally insulated outer shell with high-density rock wool mattress, externally protected by pre-painted aluminum casing

Standard Supply Composition:

– Steam outlet shut-off flow valve

– Spring-loaded safety valves

– Reflective level indicators with flanged connections

– Large dial pressure gauge

– Safety pressure switch

– Limit pressure switch

– Regulation pressure switch for burner control

– Low water level safety probes

– Water level probes for pump ON-OFF

– Vertical centrifugal pump for water loading

– Water supply circuit with shut-off flow valve

– Water drain/sludge discharge group

– Manhole and inspection port

– Moisture separator on the steam outlet

– Turbulators

– Lifting hooks

– Electrical panel

– Standard documentation

Options:

– Second boiler water feed pump kit

– Inlet water filter kit

– EC kit for integrated economizer

– Maximum level safety kit

– TDS kit

– Automatic bottom drain kit

– Burner plate customization

– Burner

Special Versions:

– BAHR’12 24 hr / 72 hr for continuous operation without supervision

Note: Efficiency values may vary based on working pressure and load conditions, particularly with economizer usage. Quantity and model configuration may vary accordingly.